Environment (27)

1. What is SONY Certification Green Partner?

Sony designates suppliers that cooperate in the production of environmentally sensitive products as Green Partners. Sony established the "Sony Green Partner Standards" in 2001 with the aim of encouraging suppliers to introduce Green Partner environmental management systems.

LEMO is committed to follow the "Green Partner Environmental Quality Approval Program" where the controlled substances are described. This document (SS-00259) regroups REACH and RoHS and other National regulations from different countries.

Under this commitment LEMO performs regular controls of all suppliers, ICP tests, Audits, self-evaluation and staff training, among others.

2. Common elements and most important differences between RoHS and REACH?

As common elements, both RoHS and REACH constrain the use of substances (prohibition or restriction on the use) and both are European regulations applicable within EEA (European Economic Area countries).

Regarding the most important differences:

• REACH regulates lifecycle of all substances in all kinds of products. RoHS regulates the use of a very limited number of substances only in electrical and electronical devices.

• Reference basis for substance content restriction: REACH -> % by weight of a part / RoHS -> % by weight of a homogenous material

3. What is article 33 of REACH?

Article 33 requires that any supplier of an article in the EU containing SVHCs above the threshold of 0.1% weight by weight must provide sufficient information to the customer to allow safe use of the article.

4. What is the Candidate List?

Under REACH, the most hazardous substances on the market are gradually being added to a list known as the 'Candidate List,' with the view of ensuring their use is correctly controlled, and that safer alternatives are found as soon as possible. The substances on this list are termed 'Substances of Very High Concern' (SVHCs).

Legally nothing prohibits it to have these substances in the product, but there is a duty to inform about the name of the molecule and ways to protect from it, within a period of 45 days after receiving the customer request.

The European Chemicals Agency (ECHA) publishes the SVHC list on its webpage: (http://echa.europa.eu/web/guest/candidate-list-table).

5. What is a homogeneous material?

A homogeneous material is either a material with a uniform composition throughout or a material that consists of a combination of materials, that cannot be disjointed or separated into different materials by mechanical actions such as unscrewing, cutting, crushing, grinding or abrasive processes.

6. What are Maximum Concentration Values (MCVs)?

Maximum Concentration Value (MCVs) are limits set by the European Commission for each RoHS-restricted substance. The limits apply to each "homogeneous material" making up a product.

The MCVs are as follows: 0.1% by weight maximum for Pb, Hg, Cr6+, PBBs, PBDEs and phthalate.

0.01% by weight maximum for Cd

7. What are the restricted substances under RoHS?

The substances restricted under RoHS are lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (Cr6+), polybrominated biphenyls (PBB), polybrominated diphenyl ethers (PBDE), and four different phthalates (DEHP, BBP, BBP, DIBP).

8. Can LEMO provide Material Declarations?

Due to the wide variation in content and format request forms, LEMO adopted its own forms in response to requests for regulatory information. LEMO can provide upon request Material Declarations on LEMO template for some specific products. Please submit your request using your usual communication channel (subsidiary, distributor).

9. Are there any SVHC in LEMO products?

Lead is a component of bronze, copper alloys and solder alloys. This substance may be present at a concentration greater than 0.1% w / w in ours articles (applications covered by EU RoHS 2 exemptions).

LEMO is committed to work on the reduction or removal of this identified SVHC whenever it is possible and to supply sufficient information to allow safe use of the substance.

10. What is REACH?

European regulation N° 1907/2006, adopted in December 2006, that establishes a single integrated system for the registration, evaluation, authorisation and restriction of chemical substances in the European Union. It applies to all areas of activity.

11. Can LEMO provide a COC RoHS?

Due to the wide variation in content and format request forms, LEMO adopted its own forms in response to requests for regulatory information. If part number is specified by the Customer, LEMO can supply a COC with mention of the LEMO part number, RoHS compliance status and number of exemption (if applicable). Please submit your request using your usual communication channel (subsidiary, distributor).

12. Are there any exemptions to RoHS? Which ones are applied to LEMO?

Yes. A list of exemptions for the use of the above substances in specific items is given in Annexes III and IV of Directive 2011/65/EU.

Exemptions applied to LEMO:

Lead (Pb):

0.35 % in steel alloy (exemption 6a – annexe III RoHS)

0.4 % in aluminium alloys (exemption 6b – annexe III RoHS)

4 % in copper alloys (exemption 6c – annexe III RoHS)

13. What is RoHS?

RoHS stands for Restriction of Hazardous Substances. Originated in the European Union as Directive 2002/95/EC, it restricts the use of specific hazardous materials found in electrical and electronic products.

On 2nd January 2013, Directive 2002/95/EC is repealed by Directive 2011/65/EU known as the recast of the RoHS Directive or as the RoHS 2 Directive.

In 2015, Directive 2015/863, known as RoHS 3, was published by the EU expanding the scope of the actual Directive by adding 4 additional restricted substances.

14. What is a homogeneous material?

A homogeneous material is either a material with a uniform composition throughout or a material that consists of a combination of materials, that cannot be disjointed or separated into different materials by mechanical actions such as unscrewing, cutting, crushing, grinding or abrasive processes.

15. What are Maximum Concentration Values (MCVs)?

Maximum Concentration Value (MCVs) are limits set by the European Commission for each RoHS-restricted substance. The limits apply to each "homogeneous material" making up a product.

The MCVs are as follows: 0.1% by weight maximum for Pb, Hg, Cr6+, PBBs, PBDEs and phthalate.

0.01% by weight maximum for Cd

16. What is SONY Certification Green Partner?

Sony designates suppliers that cooperate in the production of environmentally sensitive products as Green Partners. Sony established the "Sony Green Partner Standards" in 2001 with the aim of encouraging suppliers to introduce Green Partner environmental management systems.

LEMO is committed to follow the "Green Partner Environmental Quality Approval Program" where the controlled substances are described. This document (SS-00259) regroups REACH and RoHS and other National regulations from different countries.

Under this commitment LEMO performs regular controls of all suppliers, ICP tests, Audits, self-evaluation and staff training, among others.

17. What is the Candidate List?

Under REACH, the most hazardous substances on the market are gradually being added to a list known as the 'Candidate List,' with the view of ensuring their use is correctly controlled, and that safer alternatives are found as soon as possible. The substances on this list are termed 'Substances of Very High Concern' (SVHCs).

Legally nothing prohibits it to have these substances in the product, but there is a duty to inform about the name of the molecule and ways to protect from it, within a period of 45 days after receiving the customer request.

The European Chemicals Agency (ECHA) publishes the SVHC list on its webpage: (http://echa.europa.eu/web/guest/candidate-list-table).

18. What is a homogeneous material?

A homogeneous material is either a material with a uniform composition throughout or a material that consists of a combination of materials, that cannot be disjointed or separated into different materials by mechanical actions such as unscrewing, cutting, crushing, grinding or abrasive processes.

19. Common elements and most important differences between RoHS and REACH?

As common elements, both RoHS and REACH constrain the use of substances (prohibition or restriction on the use) and both are European regulations applicable within EEA (European Economic Area countries).

Regarding the most important differences:

• REACH regulates lifecycle of all substances in all kinds of products. RoHS regulates the use of a very limited number of substances only in electrical and electronical devices.

• Reference basis for substance content restriction: REACH -> % by weight of a part / RoHS -> % by weight of a homogenous material

20. What is article 33 of REACH?

Article 33 requires that any supplier of an article in the EU containing SVHCs above the threshold of 0.1% weight by weight must provide sufficient information to the customer to allow safe use of the article.

21. Can LEMO provide Material Declarations?

Due to the wide variation in content and format request forms, LEMO adopted its own forms in response to requests for regulatory information. LEMO can provide upon request Material Declarations on LEMO template for some specific products. Please submit your request using your usual communication channel (subsidiary, distributor).

22. Are there any SVHC in LEMO products?

Lead is a component of bronze, copper alloys and solder alloys. This substance may be present at a concentration greater than 0.1% w / w in ours articles (applications covered by EU RoHS 2 exemptions).

LEMO is committed to work on the reduction or removal of this identified SVHC whenever it is possible and to supply sufficient information to allow safe use of the substance.

23. What is REACH?

European regulation N° 1907/2006, adopted in December 2006, that establishes a single integrated system for the registration, evaluation, authorisation and restriction of chemical substances in the European Union. It applies to all areas of activity.

24. What are the restricted substances under RoHS?

The substances restricted under RoHS are lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (Cr6+), polybrominated biphenyls (PBB), polybrominated diphenyl ethers (PBDE), and four different phthalates (DEHP, BBP, BBP, DIBP).

25. Can LEMO provide a COC RoHS?

Due to the wide variation in content and format request forms, LEMO adopted its own forms in response to requests for regulatory information. If part number is specified by the Customer, LEMO can supply a COC with mention of the LEMO part number, RoHS compliance status and number of exemption (if applicable). Please submit your request using your usual communication channel (subsidiary, distributor).

26. Are there any exemptions to RoHS? Which ones are applied to LEMO?

Yes. A list of exemptions for the use of the above substances in specific items is given in Annexes III and IV of Directive 2011/65/EU.

Exemptions applied to LEMO:

Lead (Pb):

0.35 % in steel alloy (exemption 6a – annexe III RoHS)

0.4 % in aluminium alloys (exemption 6b – annexe III RoHS)

4 % in copper alloys (exemption 6c – annexe III RoHS)

27. What is RoHS?

RoHS stands for Restriction of Hazardous Substances. Originated in the European Union as Directive 2002/95/EC, it restricts the use of specific hazardous materials found in electrical and electronic products.

On 2nd January 2013, Directive 2002/95/EC is repealed by Directive 2011/65/EU known as the recast of the RoHS Directive or as the RoHS 2 Directive.

In 2015, Directive 2015/863, known as RoHS 3, was published by the EU expanding the scope of the actual Directive by adding 4 additional restricted substances.

Searching on website (5)

1. PRODUCT FINDER did not find a connector based on my entry. How should I modify my entry to increase the likelihood?

It depends on which search you use. Here are some of the more common scenarios:

Part Number Search:

Common typographical errors include:

Using the digit "5" instead of the letter "S" and vice-versa

Using the letter "I" instead of the digit "1"

Using the letter "7" instead of the letter "Z" and vice-versa

If you cannot resolve this issue, please contact us at info@lemo.com for further assistance.

Advanced (or occasionally basic) Search:

Check your color requirement. Your connector of choice might be in the database in other colors (contact LEMO to get your color).

Clear the Cable Ø fields and repeat the search.

Do not specify a connector diameter or length unless it is absolutely critical.

the S Series instead of B and vice versa (same for E and K).

Choose a different Shell Style.

Try both solder and crimp termination, or printed circuit board (PCB).

You can also use the Connector Design Connector Quote Form for further assistance from LEMO (typically takes one business day).

Product Details Page:

Change the sequence if you want to modify more than one parameter, or go to the advanced search page and start over.

2. What do the following terms mean in the connector SEARCH (Product Finder)?

Low voltage contact

A low voltage contact has no additional protection, such as an insulating sleeve, and is intended to run low voltages.

However, depending on the distance to other contacts and the shell, its breakdown voltage under laboratory conditions can still be hundreds, or even a few thousand volts.

LEMO recommends applying only operating voltages low enough to be considered safe in the target application.

Download the Concentric Contact Identification Guide for illustrative comparisons.

High voltage contact

A high voltage contact has an additional insulating sleeve that provides longer creepage distances.

It allows high voltages over a wide range of temperatures, humidity, and altitudes. In general, its breakdown voltage tends to be higher compared to low voltage contacts.

The additional insulator can also reduce the risk of touching a dangerous voltage (LEMO recommends to always turn off power before disconnecting any type of connector).

Download the Concentric Contact Identification Guide for illustrative comparisons.

Coaxial contact

A coaxial contact is a concentric mechanical design to achieve a given electrical impedance.

Electrical impedance is the ratio of the electrical field and the magnetic field of a wave traveling in a cable or through a connector and should not be confused with the contact resistance (typically a very small fraction of one ohm).

Typical electrical impedances are 75 ohm for audio and video signals (analog radio and television) and 50 ohm for most other applications.

Download the Concentric Contact Identification Guide for illustrative comparisons.

Triax contact

A triaxial contact is a coaxial contact with an additional shielding.

Triaxial cables and contacts provide better electromagnetic compatibility (EMC) and cause less radio-frequency interference (RFI).

Because they are most common in the broadcast industry, they usually have 75 ohm impedance.

Quadrax contact

A quadrax connector design has a center contact plus three concentric contacts, allowing connection of four wires.

Because you can rotate the connector in any direction it provides convenience. Quadrax designs often are used for audio (stereo) applications.

In general they do not have a controlled impedance.

Download the Concentric Contact Identification Guide for illustrative comparisons.

Thermocouple contact

A thermocouple is an electric temperature sensor consisting of two different metals.

In order to reduce measurement errors due to temperature differences in a connector, it is important that connector contact materials match the metals used to make the temperature sensor.

LEMO's thermocouple connectors have pairs of thermocouple contacts (enter number of contacts = 2, 4, 6, etc. in "Thermocouple" on the Advanced Search page).

To specify a thermocouple connector with a grounding contact, enter 2 in "Thermocouple" and 1 in "Low Voltage".

Fluidic/pneumatic contact

Fluidic contacts for medical, dental and industrial applications allow you to connect single or multiple tubes and hybrid electrical/fluidic cables. They can also be used for air.

Fiber Optic

LEMO offers a variety of ceramic and metal ferrules that can accept different fibers.

These ferrules are grouped into four categories.

Each category has been designed for a certain number of contacts (type F1/F2: multiple fiber optic or electrical/optical hybrids, type F3/F4: connectors with just one fiber optic contact) and ferrule hole sizes (type F2/F4: 125 to 140 um, type F1/F3: 140 to 1650 um).

Shell Style

Shell Style is a way of grouping connectors into categories. The most common shell styles are free (straight or elbow) plugs and fixed (front/rear mount) receptacles.

"Front mount" indicates that the connector normally is mounted from the outside (front side) of a panel. "Rear mount" indicates that the connector normally is mounted from the inside (rear side) of a panel. Printed circuit board connectors in general belong to the "rear mount" style because most of them are soldered in place before the board gets mounted inside a chassis.

Insert Style

Insert Style groups various contact configurations, such as single contact, multiple contact, coaxial, fiber optic, hybrid, etc.

Termination Style

Termination Style describes how you connect your cable or printed circuit board to the connector.

Solder: soldered to a stranded or solid wire.

Crimp: used for stranded wires.

Printed Circuit Board: has straight leads.

Elbow-PCB: has 90 degree elbow leads to a through-hole printed circuit board.

Fiber optic terminates, optical fiber, and Fluidic/Pneumatic: intended for tubes.

Thermocouple: special solder contacts for sensors based on the thermoelectric effect.

Explanation of frequently-used acronyms seen in searching connectors:

LV: | Low Voltage contact(s) |

HV: | High Voltage contact(s) |

CX: | Coaxial contact(s) |

TX: | Triaxial contact(s) |

QD: | Quadraxial contact(s) |

FO: | Fiber optic contact(s) |

ThC: | Thermocouple contact(s) |

Fl/Pn: | Fluidic/pneumatic contact(s) |

Z: | Coaxial or triaxial impedance (50 or 75 Ohm) |

Ø | Diameter in mm (unless specified otherwise) |

PCB: | Printed Circuit Board |

PCB-90: | Elbow (90 degree) design for printed circuit board |

3. What does Readily Available Parts mean on the LEMO web site?

Non-standard parts have unique features to meet specific applications, and typically take 6-12 weeks to deliver.

Because it takes only one non-standard component to make a product no longer readily available, the less specific you are in the advanced search, the wider the range of search results.

The search engine tends to default to readily available parts whenever possible.

4. How does the advanced SEARCH apply Volts and Amps to hybrid connectors or those with different pin sizes?

In general, the search engine makes sure that at least one contact meets or exceeds required "Volts" entry, and at least one meets or exceeds the "Amps" criterion.

For example, the 2B.708 insert has one high voltage contact (8,000 Volts, 4 Amps) and eight low voltage contacts (750-1,500 Volts, 10 Amps).

The software will compare your voltage criterion with the best-case voltage specification (in this case, high voltage contact) and the best-case current specification (in this case, low voltage contact).

In some hybrids, the same contact exceeds both criteria; in some others, like the example above, two different contacts qualify. For more information, please refer to the pdf catalog document.

5. The web site displays product details different than the LEMO catalog. Which one is right?

Despite extra care, changes or typographical and other errors may occur after the catalog is printed.

Please report a discrepancy by contacting info@lemo.com.

LEMO will correct the information in the catalogs, and update the web site.

Also, please be advised that specifications, drawings, and other technical information are subject to change at any time and without notice.

If you depend on particular features, properties, or performance characteristics, then please contact info@lemo.com LEMO to discuss your individual needs.

Technical (1)

1. What is an IP rating?

IP stands for Ingress Protection.

International Electrotechnical Commission - IEC 60529 "Degrees of protection provided by enclosures (IP Code)"

NEMA offers a similar rating system.

Definition of degree of protection (IP code)

IEC 60529 outlines an international classification system for the sealing effectiveness of enclosures of electrical equipment against the intrusion of foreign bodies (e.g., tools, dust, fingers, and moisture) into the equipment. This classification system utilizes the letters IP (Ingress Protection) followed by two digits.

Degree of protection - First digit

The first digit of the IP code indicates the degree that the connector is protected against contact with moving parts, as well as the degree to which equipment is protected against solid foreign bodies intruding into an enclosure:

0 No special protection.

1 Protection from a large part of the body such as hand or from solid objects greater than 50 mm in diameter.

2 Protection against objects not greater than 80 mm in length and 12 mm in diameter.

3 Protection from entry by tools, wires, etc., with a diameter or thickness greater than 2.5 mm.

4 Protection from entry by solid objects with a diameter or thickness greater than 1.0 mm.

5 Protection from the amount of dust that would interfere with the operation of the equipment.

6 Dust-tight.

Degree of protection - Second digit

The second digit indicates the degree of protection of the equipment inside the enclosure against the harmful entry of various forms of moisture (e.g., dripping, spraying, submersion, etc.).

0 No special protection.

1 Protection from vertically dripping water.

2 Protection from dripping water when tilted up to 15°.

3 Protection from sprayed water.

4 Protection from splashed water.

5 Protection from water projected from a nozzle.

6 Protection against heavy seas, or powerful jets of water.

7 Protection against temporary immersion.

8 Protection against complete continuous submersion in water (up to 1 meter deep for 15 minutes).

Technical references (3)

1. What is an NEMA rating, and how do I cross-reference with an IP rating?

Two widely accepted rating systems are the NEMA and the IP codes. NEMA, short for National Electric Manufacturers' Association, is commonly specified at installations in the U.S.A. IP, which is an abbreviation for International Protection, is derived from the IEC.

IP and IEC are more common in Europe and Asia.

NEMA Definitions

Here are the NEMA 250 classifications:

| 1 | Intended for use primarily to provide a degree of protection against limited amounts of falling dirt. |

| 3 | Outdoor protection against rain, sleet, windblown dust, and damage from external ice formation. |

| 3R | Outdoor, protection against rain, sleet, and damage from external ice formation. |

| 3S | Outdoor, protection against rain, sleet, windblown dust, and to provide for operation of external mechanisms when ice laden. |

| 4 | Indoor/Outdoor, protection against windblown dust and rain, splashing water, hose-directed water & damage from external ice formation. |

| 4X | Indoor/Outdoor, protection against corrosion, windblown dust and rain, splashing water, hose-directed water & damage from external ice formation. |

| 6 | Indoor/Outdoor, protection against hose-directed water, the entry of water during occasional temporary submersion at a limited depth & damage from external ice formation. |

| 6P | Indoor/Outdoor, protection against hose-directed water, the entry of water during prolonged submersion at a limited depth & damage from external ice formation. |

| 12 | Indoor, protection against circulating dust, falling dirt and dripping non-corrosive liquids. |

| 12K | Type 12 with knockouts |

A Brief Comparison of NEMA 250 and IEC 60529

| NEMA Enclosure | IEC Enclosure |

| 1 | IP10 |

| 3 | IP54 |

| 3R | IP14 |

| 3S | IP54 |

| 4 & 4X | IP56 |

| 6 & 6P | IP67 |

| 12 & 12K | IP52 |

2. How does the AC Voltage specifications relate to the DC voltage specifications?

In general the AC voltage assumes a 50-60 Hz sinusoidal waveform and is the RMS (root mean squared) value.

The DC Voltage ratings are the AC voltage values times 1.41 (usually rounded).

3. How does the AC Current specifications relate to the DC Current specifications?

In general heat generation and dissipation limits the maximum current for a contact.

Because an AC (rms) current of the same amount as a DC current causes the same power loss for a given contact resistance, the maximum current specification is the value for DC and AC (rms).

Terms meaning in the Product Finder (7)

1. Explanation of frequently-used acronyms seen in searching connectors:

LV: Low Voltage contact(s)

HV: High Voltage contact(s)

CX: Coaxial contact(s)

TX: Triaxial contact(s)

QD: Quadraxial contact(s)

FO: Fiber optic contact(s)

ThC: Thermocouple contact(s)

Fl/Pn: Fluidic/pneumatic contact(s)

Z: Coaxial or triaxial impedance (50 or 75 Ohm)

Ø: Diameter in mm (unless specified otherwise)

PCB: Printed Circuit Board

PCB-90: Elbow (90 degree) design for printed circuit board

2. Insert Style

Insert Style groups various contact configurations, such as single contact, multiple contact, coaxial, fiber optic, hybrid, etc.

3. Quadrax contact

A quadrax connector design has a center contact plus three concentric contacts, allowing connection of four wires.

Because you can rotate the connector in any direction it provides convenience. Quadrax designs often are used for audio (stereo) applications.

In general they do not have a controlled impedance.

Download the Concentric Contact Identification Guide for illustrative comparisons.

4. Triax contact

A triaxial contact is a coaxial contact with an additional shielding.

Triaxial cables and contacts provide better electromagnetic compatibility (EMC) and cause less radio-frequency interference (RFI).

Because they are most common in the broadcast industry, they usually have 75 ohm impedance.

Download the Concentric Contact Identification Guide for illustrative comparisons.

5. Coaxial contact

A coaxial contact is a concentric mechanical design to achieve a given electrical impedance.

Electrical impedance is the ratio of the electrical field and the magnetic field of a wave traveling in a cable or through a connector and should not be confused with the contact resistance (typically a very small fraction of one ohm).

Typical electrical impedances are 75 ohm for audio and video signals (analog radio and television) and 50 ohm for most other applications.

Download the Concentric Contact Identification Guide for illustrative comparisons.

6. High voltage contact

A high voltage contact has an additional insulating sleeve that provides longer creepage distances.

It allows high voltages over a wide range of temperatures, humidity, and altitudes. In general, its breakdown voltage tends to be higher compared to low voltage contacts.

The additional insulator can also reduce the risk of touching a dangerous voltage (LEMO recommends to always turn off power before disconnecting any type of connector).

Download the Concentric Contact Identification Guide for illustrative comparisons.

7. Low voltage contact

A low voltage contact has no additional protection, such as an insulating sleeve, and is intended to run low voltages.

However, depending on the distance to other contacts and the shell, its breakdown voltage under laboratory conditions can still be hundreds, or even a few thousand volts.

LEMO recommends applying only operating voltages low enough to be considered safe in the target application.

Download the Concentric Contact Identification Guide for illustrative comparisons.

Robotic applications (3)

1. Does LEMO have connectors to facilitate robotic connections using robot telemanipulator action?

Yes. The LEMO N Series Connector was designed specifically for robotics use in telemanipulator applications.

In addition, LEMO has several models in LEMO B Series, S Series, K Series, and E Series connectors, which are also suitable.

Please see LEMO guide to Selecting a LEMO Remote Handling Connector for more detailed information

2. Does LEMO have gamma radiation tolerant (rad-hardened) connectors?

Yes, LEMO has several connector series that have optional Stainless Steel shells, PEEK inserts, and for wet environments the sealed versions have optional EPDM seals. (Note: EDPM seals are standard on the N Series).

Please see LEMO guide to Selecting a LEMO Remote Handling Connector for more detailed information

3. Does LEMO have remote handling or telemanipulator connectors for low power manipulators?

Yes, the "Y" type units on the LEMO N Series have a lever to assist with mating and unmating.

Please see LEMO guide to Selecting a LEMO Remote Handling Connector for more detailed information.

Fiber optic connector (4)

1. I plan to terminate LEMO fiber optic connectors at my site. What are the tools I would need to complete the task?

The type of connector chosen (single or multi-fiber, hybrid, sealed or not sealed), determines the tools required to terminate LEMO fiber optic connectors.

For your convenience, LEMO has gathered the most common tools and accessories for 125 mm fiber connector assembly into a single kit, complete with a carrying case.

For advice on terminating the various types of LEMO fibre optic connectors please contact your local LEMO supplier.

Instructions include the following guide lines

- 900um Buffered Fibre

- Tight Jacket Cable

- Multiway Optical Cable

- Multiway Hybrid Cable

- Hand Polishing Instructions

- Machine Polishing Instructions

2. What is the significance of the "W" keyway code in the 3K.93C HDTV fiber optic connector part numbers?

In order to ensure safety to the system and users, the "W" five-key system is assigned exclusively to the HDTV broadcast camera connectors (see ANSI/SMPTE 304M-1998/311M-1998, ARIB BTA S-1005B or EBU R100-1999).

In other cases select a different key code (for example, "G" or "A" or "J").

3. What does the letter Z signify as a contact code in LEMO fiber optic connectors?

A "Z" usualy designates no electric contacts. If the connector configuration calls for only fiber optic contacts, the letter "Z" must be entered in the contact code location to ensure proper encoding of the part number.

Example: the FGG.3K.03A.CLZC65 is a straight plug with a cable collet and two holes for fiberoptic contacts . Note that you must order the two fiber optic contacts separately.

4. In LEMO fiber optic connectors, what is a "T-adapter"?

The "T-adapter" is a component supplied with the LEMO K series fiber optic connectors that facilitates the secure attachment of the cable jacket to the rear of the connector, and permits an epoxy type moisture seal, preventing moisture ingress in to the cable from that junction.

For further details see "Cable Fixing" in the Technical Library.

Environmentally sealed (2)

1. How can I achieve an IP68 Rating with LEMO's K&E Environmentally sealed connectors?

LEMO publishes a rating of IP66/68 for LEMO K&E Series connectors.

There are 3 sealing points on a typical mated pair.

- Seal between the plug and receptacle

- Seal between the receptacle and the panel

Seal between the plug and the cable

IP68 is achieved for points 1 and 2. The connector to cable seal is highly dependant on the shape of the cable, therefore it can range from IP66 to IP68.

For complete details, please see LEMOs IP66-68 Rating Reference Guide for K&E Series Connectors.

2. Which of the LEMO F Series panel mount receptacle have seals and which do not?

The EH_, HE_ and ED_ have a front panel seal. The EG_, EC_, EE_, PE_ and PB_ do not.

Certifications & Standards (5)

1. Do LEMO connectors have UL / CSA recognition?

Yes, many LEMO connectors have Underwriters Laboratories (UL) recognition and UL for Canada recognition.

For further details go directly to the UL website and search by the file number:E119802.

2. Does LEMO have ISO certification?

LEMO worldwide is ISO 9001 certified.

Download the certificate

3. Are any of the LEMO connectors built to a specific connector standard?

Yes, two product series are built to standards, the LEMO NIM-CAMAC 00 Series, and the LEMO 3K.93C HDTV Camera Connector (see www.smpte.org for the standards).

LEMO NIM-CAMAC 00 Series

NIM modules (Nuclear Instrumentation Methods) are used to collect scientific data in nuclear particle research.

The NIM-CAMAC 00 Series front panel connectors are defined in this standard, NBS-549. View the NIM-CAMAC 00 Series.

LEMO HTDV Camera Connector – 3K.93C Series

The 3K.93C Series is used in the High Definition Television (HDTV) industry.

The standard is the ANSI/SMPTE 304M-1998 "Television - Broadcast Cameras - Hybrid Electrical and Fiber optic Connector."

The associated UL safety standard is UL1419 "Professional Video and Audio Equipment."

4. Does LEMO have MIL-SPEC connectors?

All LEMO connectors are tested to MIL standard test requirements (see table below).

LEMO's F & M Series connectors meet or exceed performance requirements of military standards (MIL spec such as MIL 810F but are currently not compatible with D38999 in dimensions connectors.

Examples of LEMO's B and F series testing include:

| Tests | MIL | Method |

| Electrical Tests | ||

| Test Voltage rms | 1344A | 3001.1 |

| Rated Voltage rms | 1344A | 3001.1 |

| Contact Resistance | 202 | 307 |

| Shell Electrical Continuity | 1344A | 3007 |

| Insulation Resistance | 1344A | 3003.1 |

| VSWR f (Ghz) | 1344A | 3005 |

| Mating Force | 1344A | 2013.1 |

| Unmating Force | 1344A | 2013.1 |

| Latching Force | 1344A | 2010.1 |

| Straight Pull force on Cable | 1344A | 2009.1 |

| Insertion Force on Contacts | 1344A | 2014 |

| Retention Force on Contacts | 1344A | 2007.1 |

| Lifetime | 1344A | 2016 |

| Vibration | 202 | 204C |

| Envirornmental Tests | ||

| Vacuum Test (if applicable) | 1344A | 1008 |

| Hydrostatic Pressure Resistance (if applicable) | 1344A | 1006.1 |

| Humidity Dependence of Working Voltage | 1344A | 1002.1 |

| Fungus | 810F | 508.5 |

| Fluid contamination (Fuels, gasoline…) | 810F | 504 |

| Sand and dust (6 hr, 55°C, blowing < 150 μm dust) | 810F | 510.4 |

| Gunfire vibration (25 to 2000 Hz, 3 axis (Apache helicopter)) | 810F | 519.5 |

| Vibration-Sine (30 g, 3 axis, 12 hr) | 202 | 204-G |

| Acceleration (50g) | 1344 | 2011-1, A |

5. What is LEMO's position in regards to the requirements of RoHS (Restriction of Hazardous Substances) legislation?

LEMO Connectors and Accessories

LEMO certifies that its connectors and accessories marketed, manufactured, and shipped after January 1, 2006 are in full compliance with the requirements of Directive 2002/95/EC of the European Parliament and of the Council dated 27th January 2003 regarding the presence of: mercury, cadmium, lead, hexavalent chromium, polybromide biphenyl (PBB) or polybromide diphenyl ether (PBDE), including DecaBDE.

The Directive (EU Directive 2002/95/EC) specifies restriction of the use of certain hazardous substances in electrical and electronic equipment by July 1, 2006 and is known as the RoHS Directive

All part numbers will remain unchanged. The vast majority of all LEMO products require no adjustment for RoHS compliance. The few items that have internal solder connections have moved to lead-free solder. There are a few connectors with an optional aluminum-alloy shell that contains lead in that alloy. For that shell option LEMO will switch to a RoHS compliant aluminum alloy by January 1, 2006.

Contacts Designed for Solder Connection

All LEMO connectors with solder-style contacts are fully compatible with lead-free solder and the required higher temperatures. LEMO insulators are made of high temperature material and the standard connecting surfaces are made of an Au/Ni plating. In addition, LEMO has conducted verification testing of contacts and cable assemblies with lead-free solder.

Cable and Product Assemblies by LEMO

Standard cable and product assemblies from LEMO use lead-free solder. Cable assemblies and other value added products that require RoHS declarations of compliance will be available by June 1, 2006. Call us if you need help with certification earlier. LEMO also continues to offer custom services to meet customer specific requirements for both material and process (such as with solder selection) in cable and other product assemblies. Lead based or lead-free soldering processes are available.

Part numbers & Connectors (1)

1. What is the meaning of the letters Y or W at the end of a part number?

The letters "Y" and in some cases "W" have been used for special designs.

In general they indicate that a catalog item has been modified in order to meet a specific need in a particular application.

Common specials can be looked-up using the Search By Part Number.

Otherwise, contact info@lemo.com to get details about what is unique in your specific part number.

General (13)

1. How do I order my plug with a bend relief?

Bend reliefs are ordered separately from plugs.

They come in various colours, and with different inside diameters.

When ordering a plug, add the variant letter "Z" to the end of the part number to specify a rear collet nut with a lip to accept the bend relief.

See Part Numbers Explained for more information about LEMO's part numbering system.

2. Does LEMO offer customer specific stocking programs?

LEMO entities in the U.S.A., Germany, United Kingdom, and in other countries hold large inventories in order to meet expected demand of products or parts.

This helps to ensure that standard parts are available within a short lead-time. For customers with significant large-volume business, LEMO offers discounts and safety stocks.

A safety stock is an amount of inventory reserved for a customer according to an existing contract.

Please contact info@lemo.com LEMO to discuss forecasts, delivery, and safety stock needs, and to negotiate an individual agreement.

3. How do I know if I have a LEMO Connector?

A LEMO plug is typically marked with the LEMO name and the first 5 characters of the part number, which represent the model, size, and series.For more information, download a detailed Plug Identification Guide. A LEMO receptacle is typically marked with the LEMO name and the first 5 characters of the part number, which represent the model, size, and series. For more information, download a detailed Receptacle Identification Guide

4. What type of thread lock material may I use on REDEL® connectors?

LEMO recommends cleaning the connector with Isopropyl Alcohol prior to thread lock adhesive.

We have a specific formulation of Vibra-Tite® for the PSU (Polysulfone) and PEI (Polyetherimide) used by LEMO, VTCS-6. For more detail, please contact us to know the assembly instructions.

5. What is a cable group?

LEMO's coaxial contacts are designed to accept a range of coaxial cables.

A LEMO cable group describes the group of cables that are compatible with a particular contact.

For example, the 2B.802 can work with cable group 1 (RG.174 A/U, RG.188 A/U, RG.316 /U), group 2 (RG.178 B/U, RG.196 A/U) and group 3 (RG.179 B/U, RG.187 A/U).

For more information, contact info@lemo.com.

6. Does LEMO have BNC adaptors?

Yes, you can find several BNC adapters referenced in the NIM-CAMAC 00 series Catalog.

7. My equipment has a LEMO receptacle with a concentric contact, how do I determine the part number?

The Concentric Contact Guide should enable you to re-create the LEMO part number for most concentric connectors.

You can also refer to Part Numbers Explained for more information.

You may need to contact LEMO for identification assistance with the following different types of concentric electrical contact connectors:

•Coax contact

•Triax contact

•Unipole contact

•High Voltage contact

When contacting LEMO please mention that you estimated or re-created this part number so that Customer Service can double-check the information.

8. Can I download PDF drawings of LEMO connector from this web site?

No, however, in the near future this feature will be added. In the meantime, you can contact info@lemo.com LEMO engineering for CAD files.

9. How does LEMO determine the maximum recommended operating voltage?

LEMO takes pride in strictly following the IEC Standard.

LEMO always has the safety of the user in mind when LEMO publishes specs or make recommendations.

LEMO determines its published Operating Voltage V(signal) specifications as follows:

Per IEC 60512-2 Test 4a Standard:

V(test) = 0.75 x V(breakdown)

V(signal) < 1/3 x V(test)

where:

V(breakdown) = Mean breakdown voltage

V(test) = Test Voltage

Substituting V(test) in equation (2) through V(test)

from equation (1) yields equation (3):

V(signal) = 1/3 x 0.75 x V(breakdown) = 1/4V(breakdown)

10. Can I distinguish a full part number from partial data on my LEMO plug or receptacle?

The 5th letter of a LEMO part number is an indication of the connector series. Other information needed to determine a full part number is as follows: How many contacts (pins) are in the insert of the connector? Is the shell soft chrome plated brass shell? Are the terminations solder or crimp? What is the diameter of the cable entering the rear of the connector (in millimetres if possible)? Is there a bend relief (strain relief) at the transition between the connector and the cable? What is the colour of the connector?

See Part Numbers Explained for more information about LEMO's part numbering system.

11. Are LEMO connector design trademark registered?

Yes. LEMO's distinctive "chocolate plate" connector design is a registered trademark US Reg 2'703'464 and Europe Registration 798'106.

The mark consists of truncated pyramidal projections formed on an outer surface of a connector, and with each truncated pyramidal projection having a square based on a square top.

12. My equipment has a LEMO multi-pin receptacle and I need the mating plug. How do I determine the LEMO part number I need?

Before LEMO can assist with a mating plug part number, we must first identify the LEMO receptacle.

First, check your equipment documentation to see if the LEMO part number is included.

If not, check the equipment manufacturer's web site to determine if they reference this information.

If the first two steps do not yield a LEMO part number download a Receptacle Identification Guide for more assistance.

13. How do I find pin n°1 on a PCB layout?

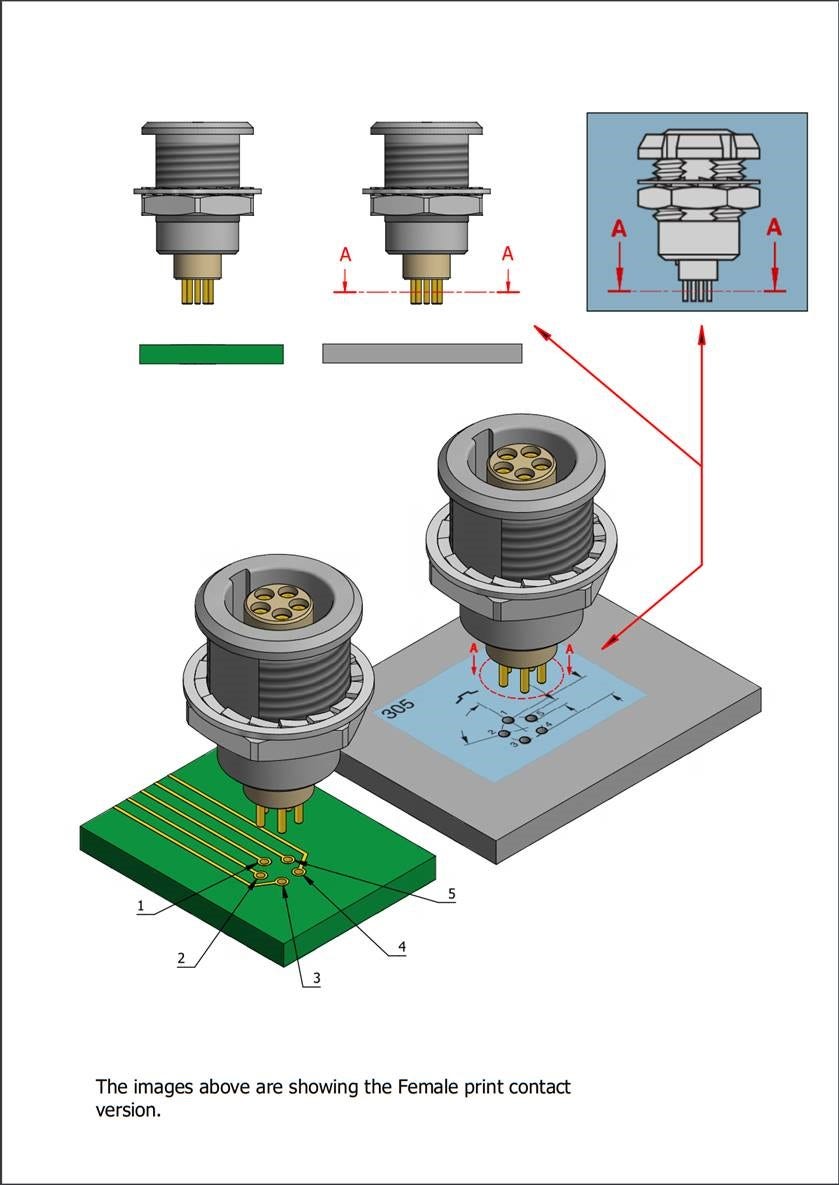

The PCB layout are shown in our Unipole/Multipole catalogue for most products of the standard LEMO range. In the case of connector with a "G" keying, contact n°1 is placed just below the key or slightly to the left side. Socket (or receptacles) are usualy fitted with female contact (part number example: ECG.1B.305.CLN). Beware, in some occasions our socket (or receptacle) can be fitted also with male contacts. Male contacts for socket ( or receptables) are called "inverted contacts" or "reverse gender", most of the time the connector uses a "J" keying (part number example: ECJ.1B.305.CLD). The following example shows a connector fitted with the standard print female contacts.

Do you

have a

challenging

project?

No matter how harsh the environment may be, LEMO has a solution ready for you to implement today.

If not, we promise to relentlessly innovate and develop one for you.

Please take a moment to reach out and describe your project, technical specifications and deadlines. We’re standing by and looking forward to hearing from you – and adding your business to our thousands of longstanding satisfied customers, partners and employees – very soon.