W - Underwater

- Screw locking

- High hydrostatic pressure environments (5 to 30 bar)

- Keying system

| Description | Description Flawless performances in highly regulated environments such as nuclear hot cells | Description High water pressure screw locking connectors designed for demanding marine and underwater applications | Description Single contact high voltage connectors in high grade materials |

| Locking | Locking Push-Pull telemanipulator | Locking Screw locking | Locking Push-Pull |

| Size | Size 4 sizes from ø 22.0 to ø 45.0 mm (plugs) | Size 6 sizes from Ø 17.2 to 50.0 mm (plugs) | Size 3 sizes from Ø 13.0 to 47.0 mm (plugs) |

| Keying | Keying 2 keyway | Keying 4 keyway | Keying No keyway (unipole) |

| Shell Types | Shell Types Special shell design | Shell Types Over 9 shell styles | Shell Types Over 19 shell styles |

| Shell Material | Shell Material Stainless steel | Shell Material Stainless steel or Brass | Shell Material Brass |

| Plating | Plating - | Plating Chrome on brass version | Plating Chrome |

| Cable Diameter | Cable Diameter 6.1 to 30.0 mm | Cable Diameter 1 to 23.5 mm | Cable Diameter 1.2 to 31.3 mm |

| NB of contact | NB of contact 2 to 64 | NB of contact 1 to 64 | NB of contact 1 |

| AWG | AWG 8 to 32 | AWG 8 to 32 | AWG 2 to 21 |

| Contact types | Contact types Multipole • Coax | Contact types Multipole • Coax • Fibre • Fluidic | Contact types High Voltage |

| Contact Termination | Contact Termination Solder / Crimp | Contact Termination Solder / Crimp / Print (PCB) | Contact Termination Solder |

| Test Voltage | Test Voltage up to 3.6 kV (rms) | Test Voltage up to 3.6 kV (rms) | Test Voltage up to 70 kV (rms) |

| Sealing Level | Sealing Level IP66 | Sealing Level IP68, 30 bars | Sealing Level IP50 |

| Temperature Range | Temperature Range -40°C to 160°C | Temperature Range -20°C to 200°C | Temperature Range -55°C to 230°C |

| Mating Cycles | Mating Cycles > 5000 | Mating Cycles > 1000 | Mating Cycles > 1000 |

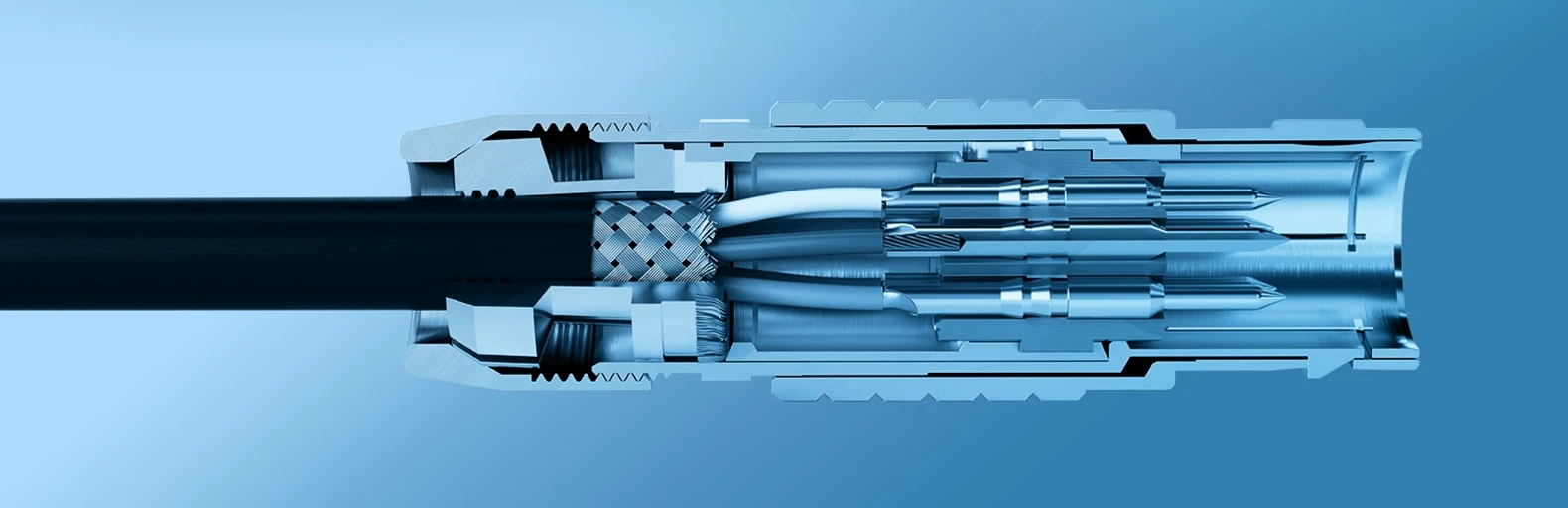

The W series is designed for high hydrostatic pressure environments, for example for underwater applications to approx. 300 metres (5 to 60 bars depending on socket size). The W series with screw locking is field-proven, and constructed for extreme conditions such as long immersion in saltwater. Multiple keys allow for high contact density and prevent mis-mating. W series connectors are suitable for test and measurement applications and the oil and gas, nuclear, chemical, marine and aerospace industries. This series offers a large selection of insert configurations, a variety of sizes and models, and electromagnetic (EMC) shielding.

- Plug

- Straight

- Nb of contacts

- 4

- Termination

- Solder

- Wire Size/AWG

- 30 - 22

- Jacket cable outside diameter [mm]

- 5.10 - 5.50 mm

- Plug

- Straight

- Nb of contacts

- 6

- Termination

- Solder

- Wire Size/AWG

- 28 - 20

- Jacket cable outside diameter [mm]

- 4.60 - 5.00 mm

- Plug

- Straight

- Nb of contacts

- 6

- Termination

- Solder

- Wire Size/AWG

- 28 - 20

- Jacket cable outside diameter [mm]

- 7.60 - 8.00 mm

- Plug

- Straight

- Nb of contacts

- 6

- Termination

- Solder

- Wire Size/AWG

- 28 - 20

- Jacket cable outside diameter [mm]

- 8.10 - 8.50 mm

- Socket / Receptacle

- Fixed Panel Front Mounted

- Nb of contacts

- 4

- Termination

- Solder

- Wire Size/AWG

- 30 - 22

- Socket / Receptacle

- Fixed Panel Front Mounted

- Nb of contacts

- 4

- Termination

- Solder

- Wire Size/AWG

- 30 - 22

- Socket / Receptacle

- Free

- Nb of contacts

- 4

- Termination

- Solder

- Wire Size/AWG

- 30 - 22

- Jacket cable outside diameter [mm]

- 4.60 - 5.00 mm

- Socket / Receptacle

- Free

- Nb of contacts

- 4

- Termination

- Solder

- Wire Size/AWG

- 30 - 22

- Jacket cable outside diameter [mm]

- 5.10 - 5.50 mm

- Socket / Receptacle

- Free

- Nb of contacts

- 4

- Termination

- Solder

- Wire Size/AWG

- 30 - 22

- Jacket cable outside diameter [mm]

- 5.60 - 6.00 mm

- Socket / Receptacle

- Free

- Nb of contacts

- 4

- Termination

- Solder

- Wire Size/AWG

- 30 - 22

- Jacket cable outside diameter [mm]

- 6.10 - 6.50 mm

- Socket / Receptacle

- Free

- Nb of contacts

- 4

- Termination

- Solder

- Wire Size/AWG

- 30 - 22

- Jacket cable outside diameter [mm]

- 6.10 - 6.50 mm

- Plug

- Straight

- Nb of contacts

- 6

- Termination

- Solder

- Wire Size/AWG

- 28 - 20

- Jacket cable outside diameter [mm]

- 8.10 - 8.50 mm

- Plug

- Straight

- Nb of contacts

- 4

- Termination

- Solder

- Wire Size/AWG

- 30 - 22

- Jacket cable outside diameter [mm]

- 5.60 - 6.00 mm

- Plug

- Straight

- Nb of contacts

- 4

- Termination

- Solder

- Wire Size/AWG

- 30 - 22

- Jacket cable outside diameter [mm]

- 5.10 - 5.50 mm

- Socket / Receptacle

- Fixed Panel Front Mounted

- Nb of contacts

- 6

- Termination

- Solder

- Wire Size/AWG

- 28 - 20

News

Innovations galore in Connected 20

Discover the 20th edition of our magazine, dedicated to innovation and innovators, showcasing varied and exciting content, that you have come to expect.

The angel wears T-shirts

In the event of a severe electric shock, reaction speed is vital. So, the Austrian company Adresys has come up with a solution that is both high-tech and discreet to detect accidents and raise the alarm : a smart T-shirt.

New multi coaxial model with High frequency performance

LEMO is thrilled to announce the expansion of its field-proven M Series with a new multi coaxial configuration, named LM.232, available in size LM with up to 12x coaxial contacts. These new plugs and fixed sockets have been specifically designed to satisfy the most stringent high frequency connection requirements under very demanding environmental conditions.This new insert configuration integrates 12x coaxial contacts type 0R (50 Ohm), allowing the transmission of high frequency data up to 26.5 GHz with a low Voltage Standing Wave Ratio (VSWR). The coaxial contact is easy to mount, thanks to its crimp contact and retaining clip. It is designed to be terminated with flexible low-loss communication cable LMR-100A or MULTIFLEX 86.Typical applications are wireless network 5G wireless networks, radar systems, battlefield communications and UAV anti-drone technology.Thanks to its expertise and cable assembly capabilities, LEMO is at your disposal to assist you in providing complete interconnect solutions.

Do you

have a

challenging

project?

No matter how harsh the environment may be, LEMO has a solution ready for you to implement today.

If not, we promise to relentlessly innovate and develop one for you.

Please take a moment to reach out and describe your project, technical specifications and deadlines. We are standing by and looking forward to hearing from you - and adding your business to our thousands of longstanding satisfied customers, partners and employees - very soon.